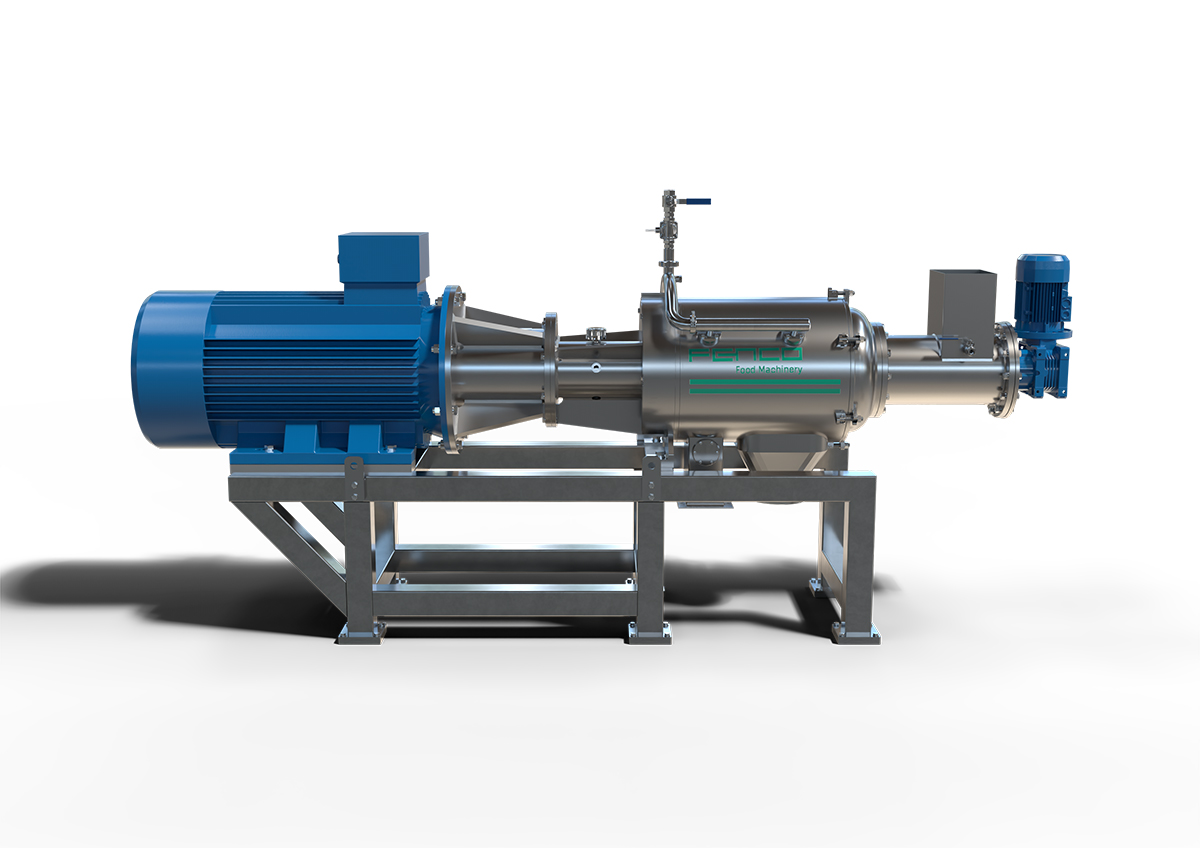

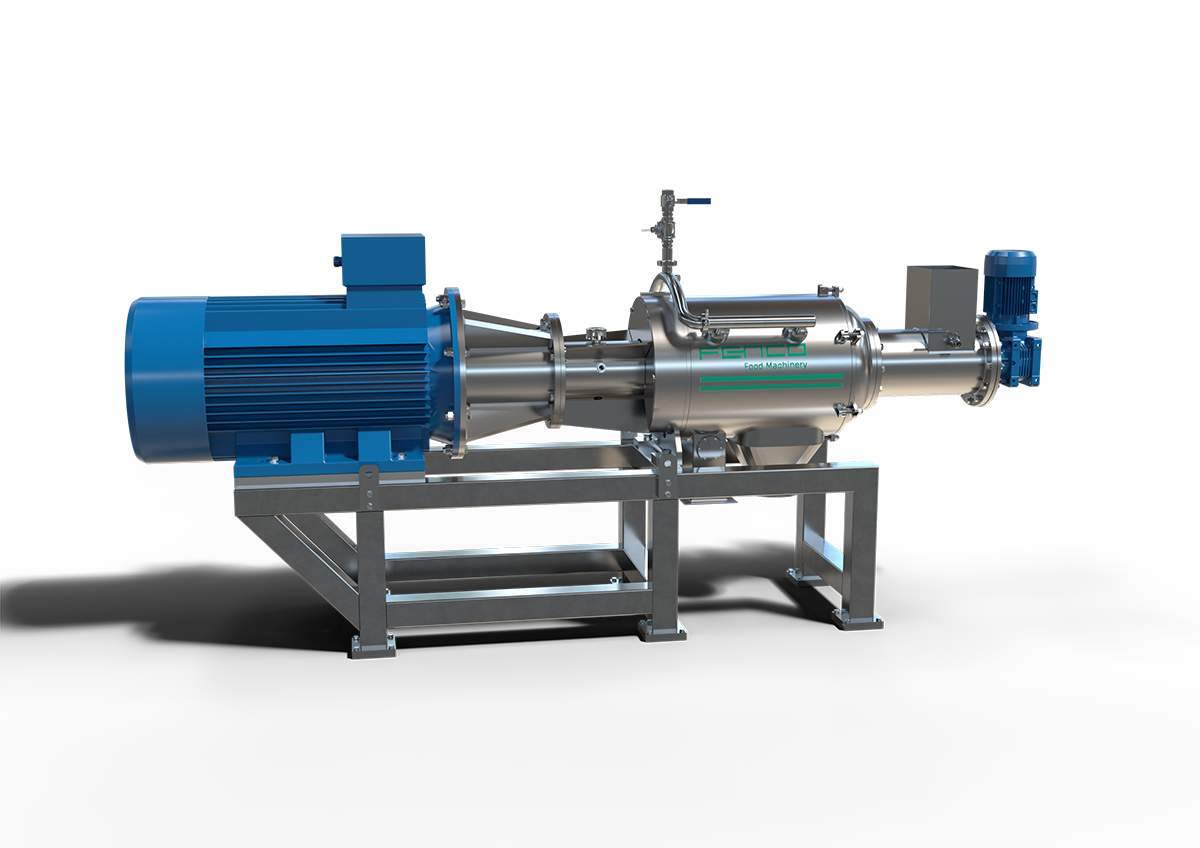

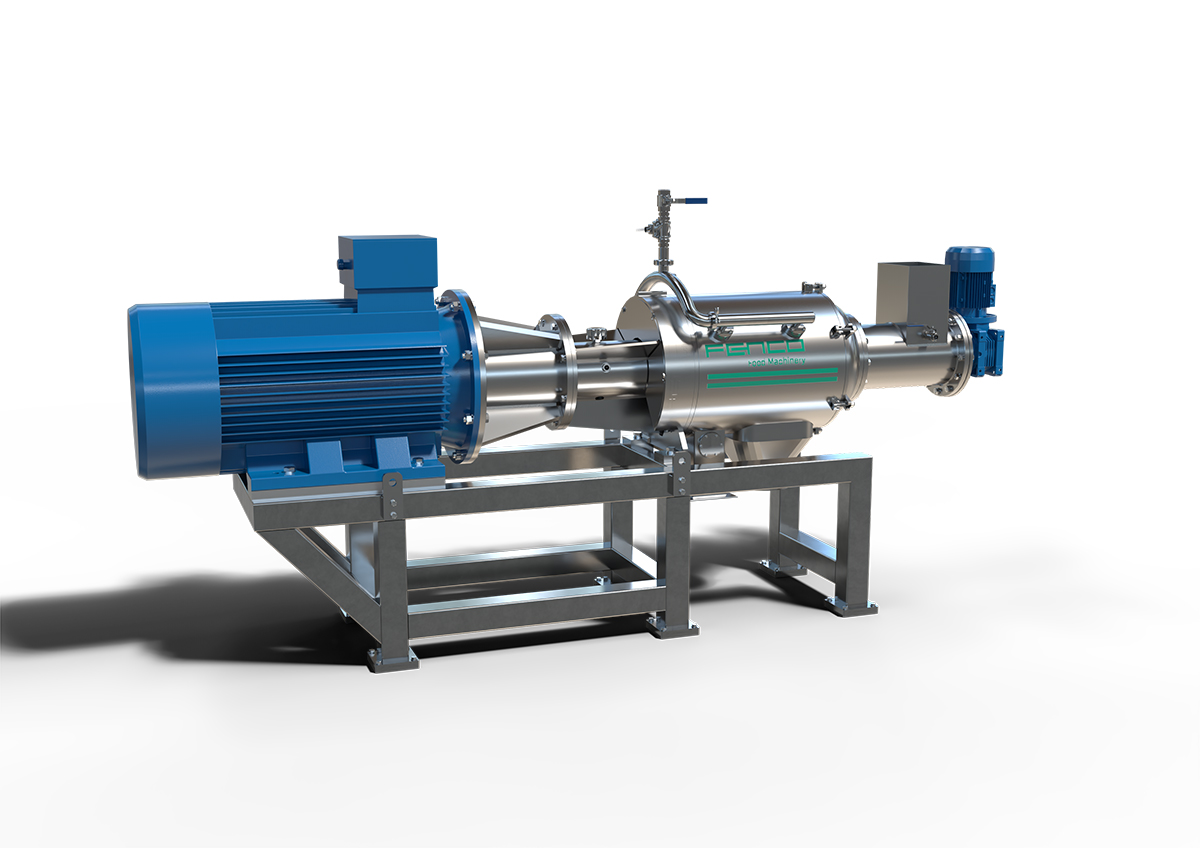

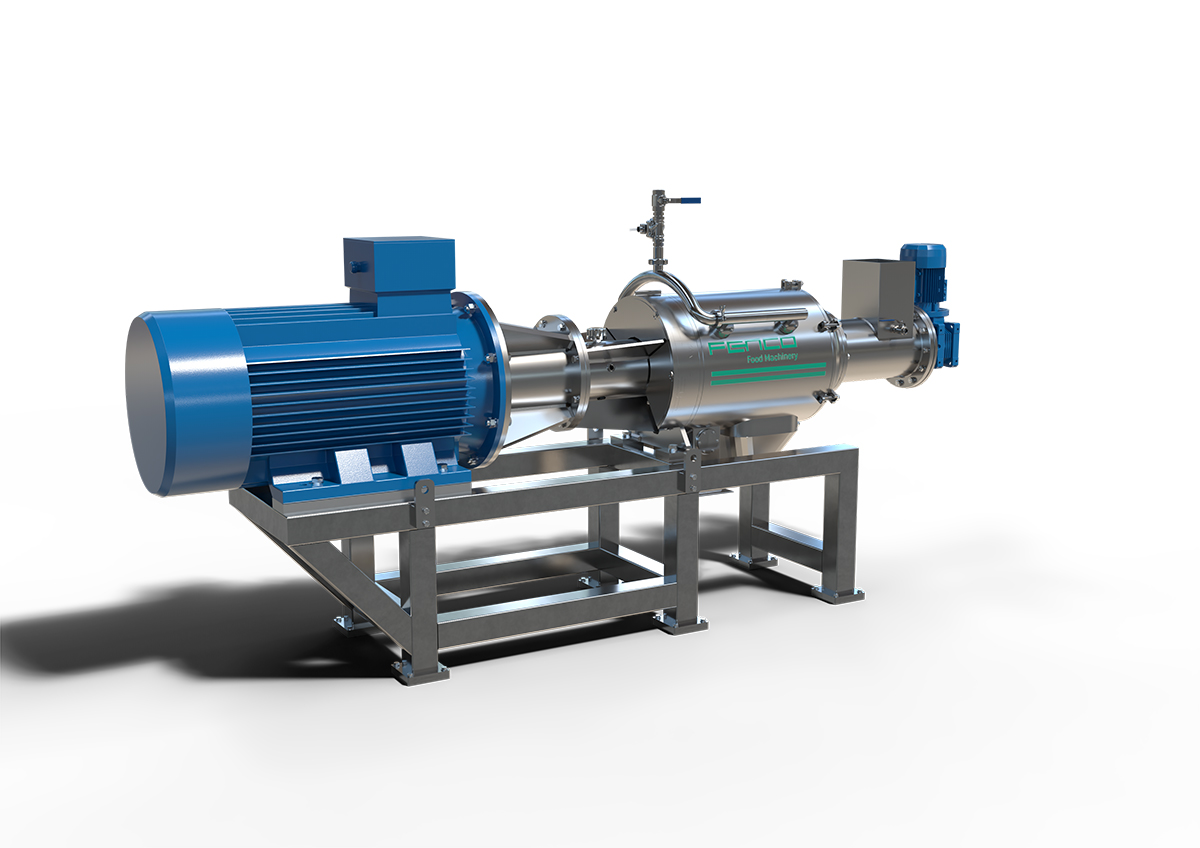

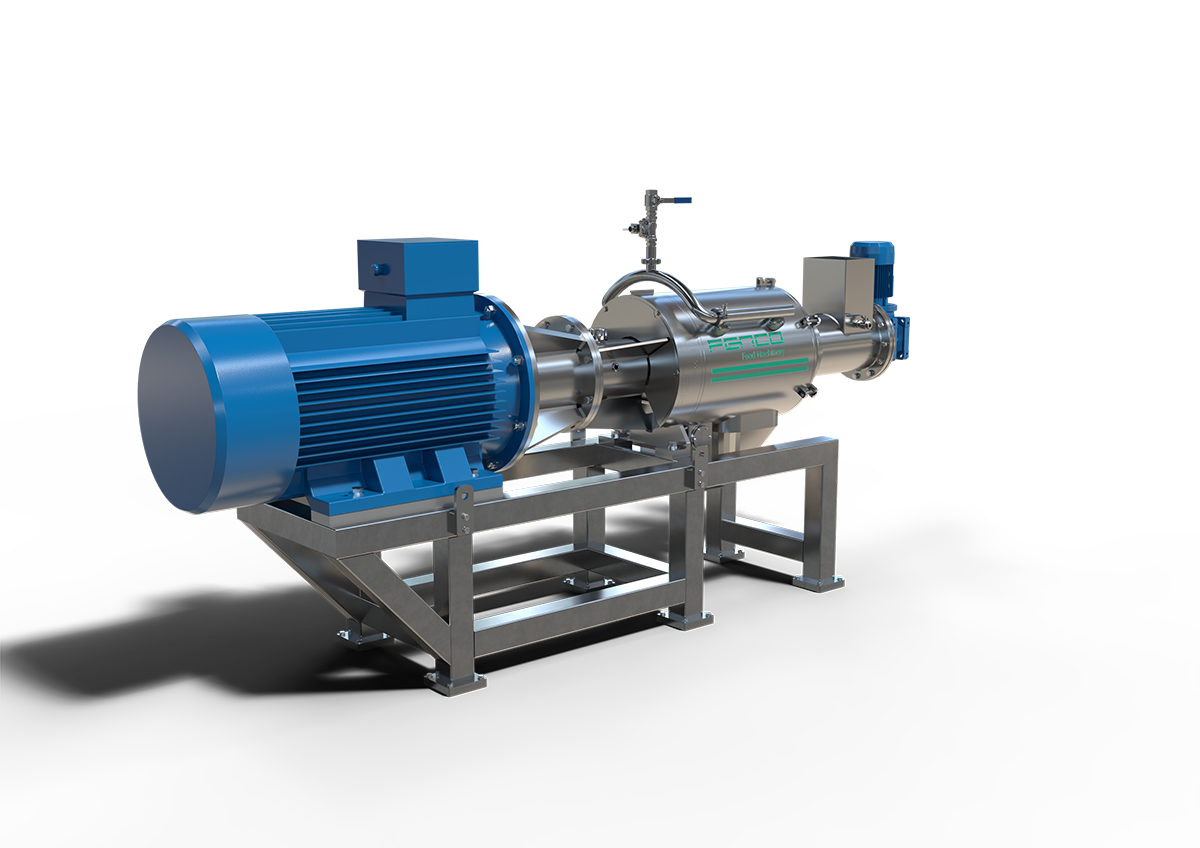

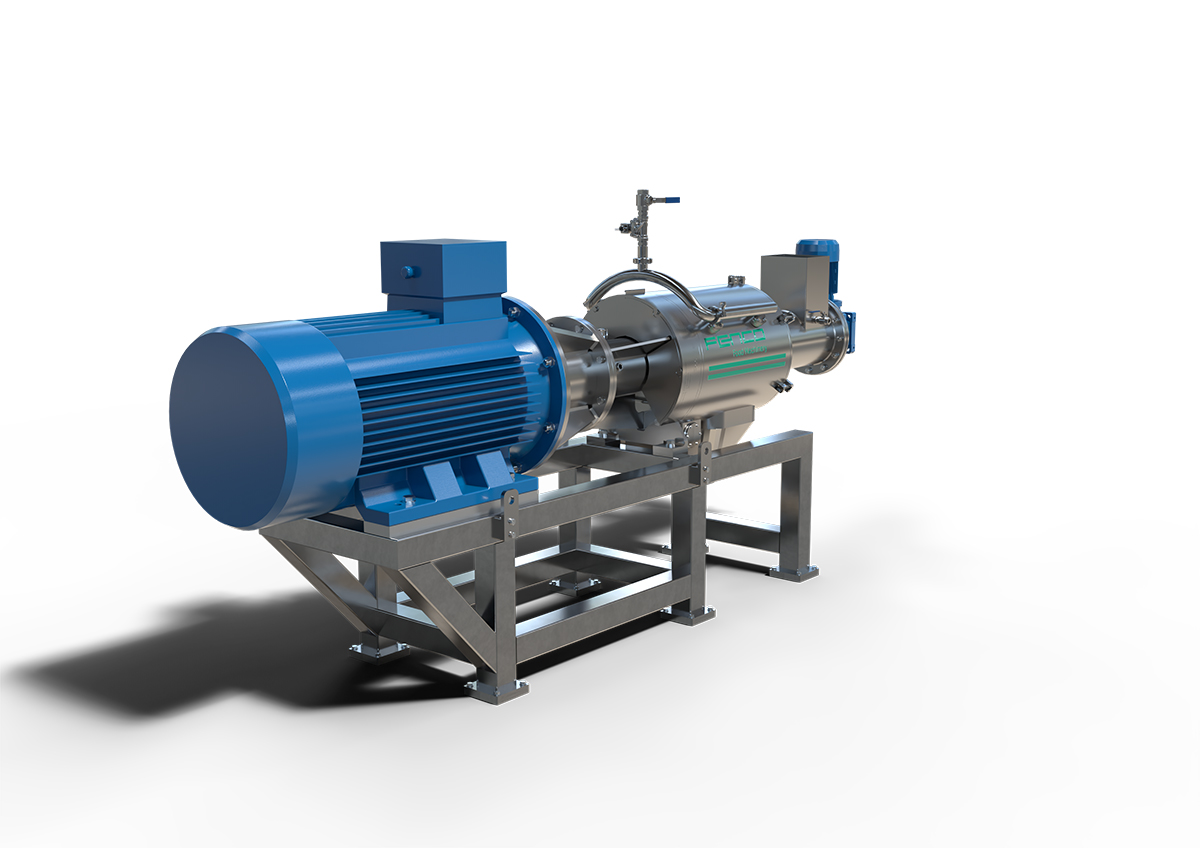

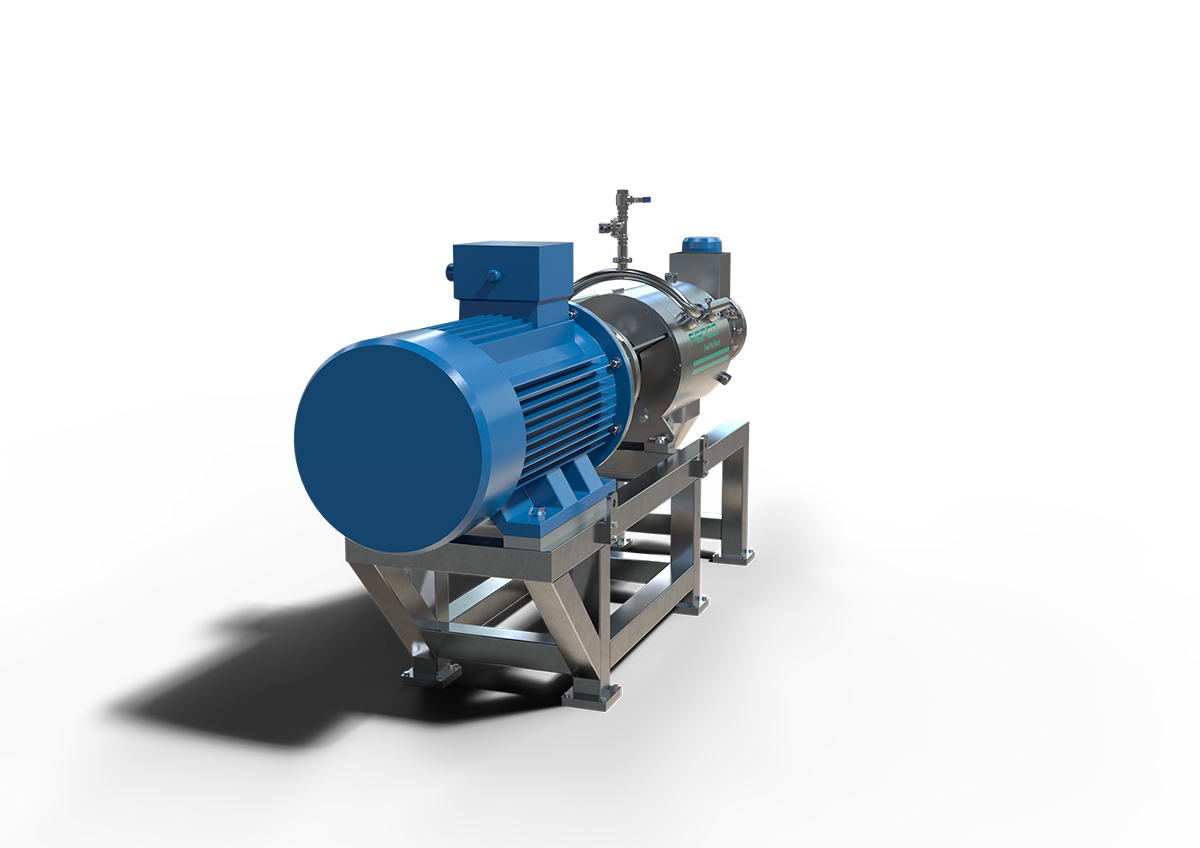

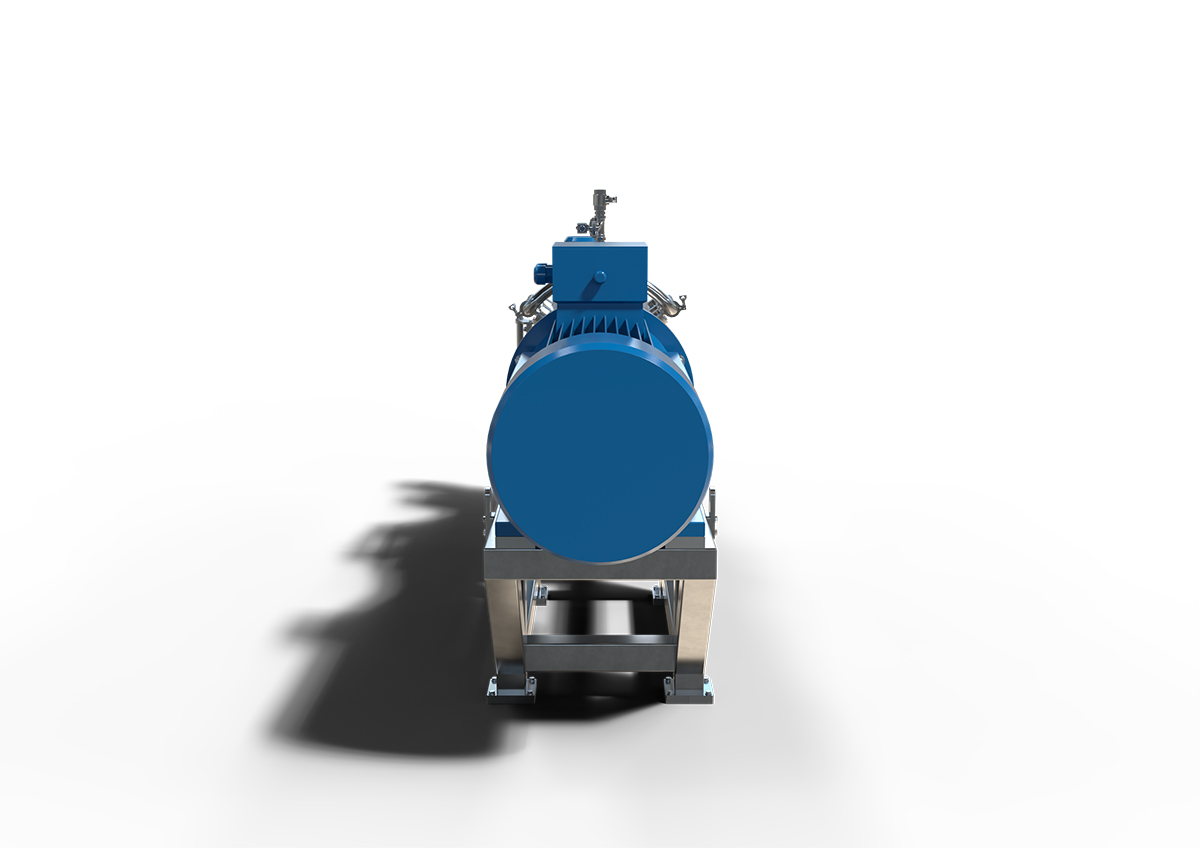

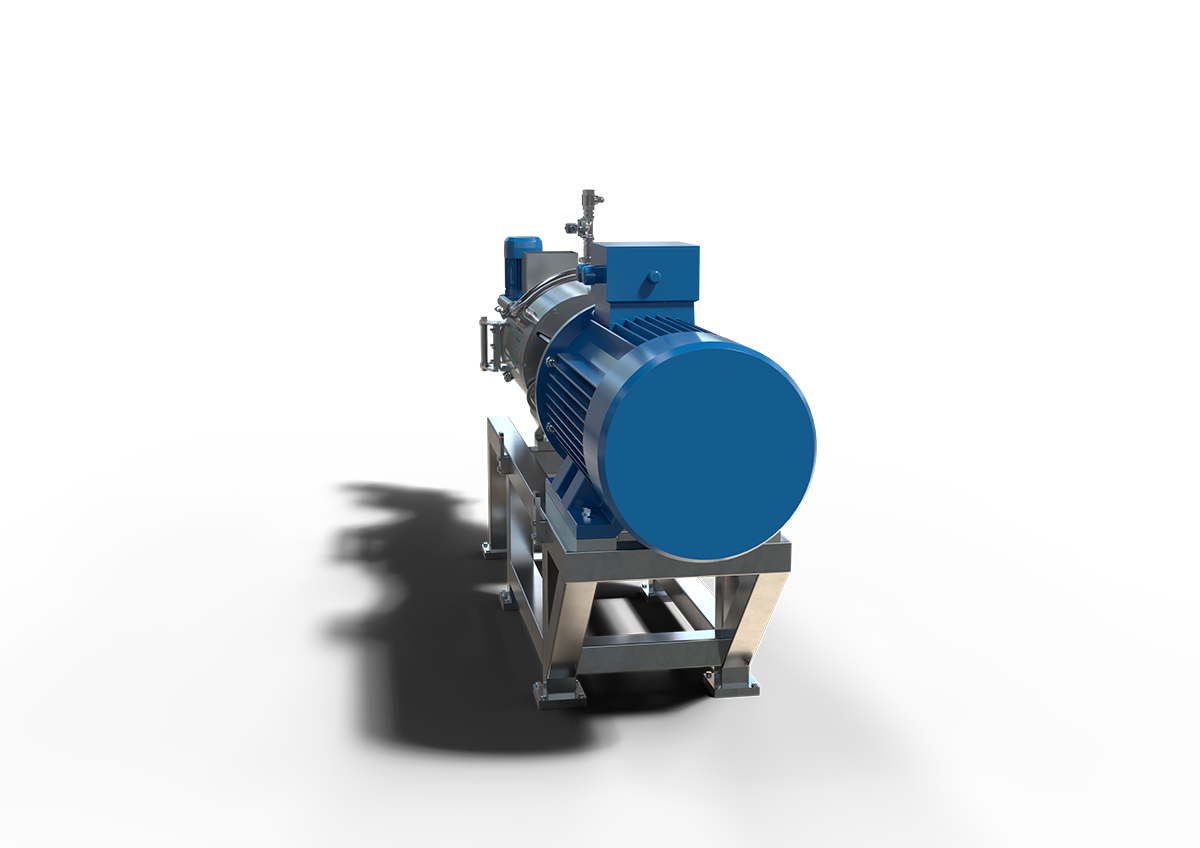

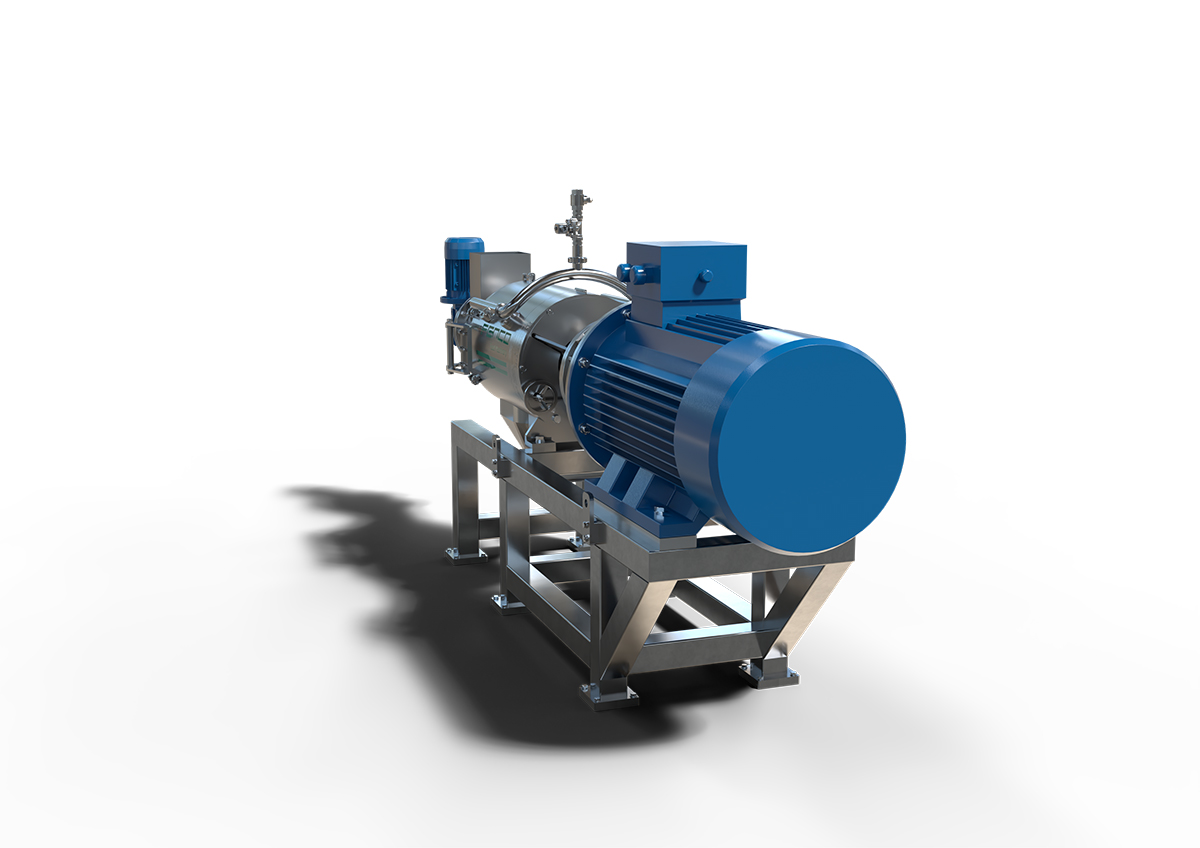

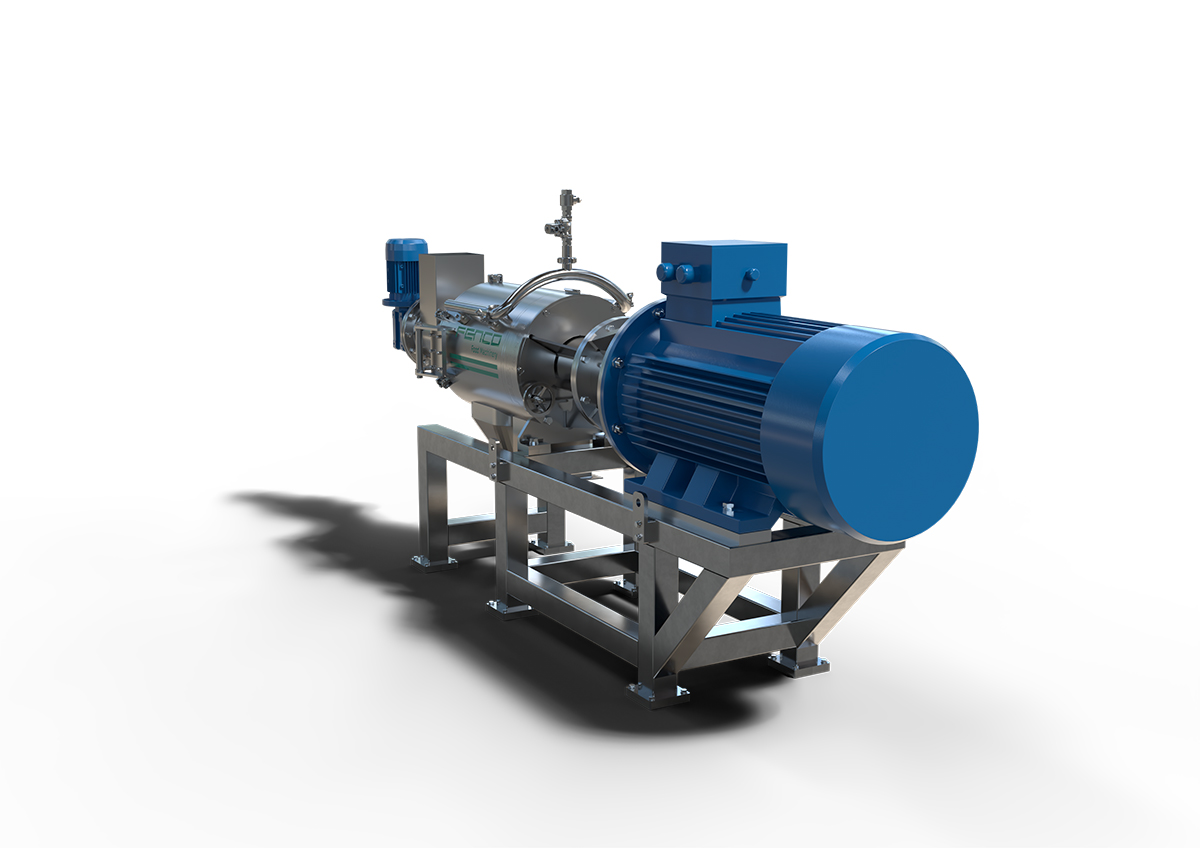

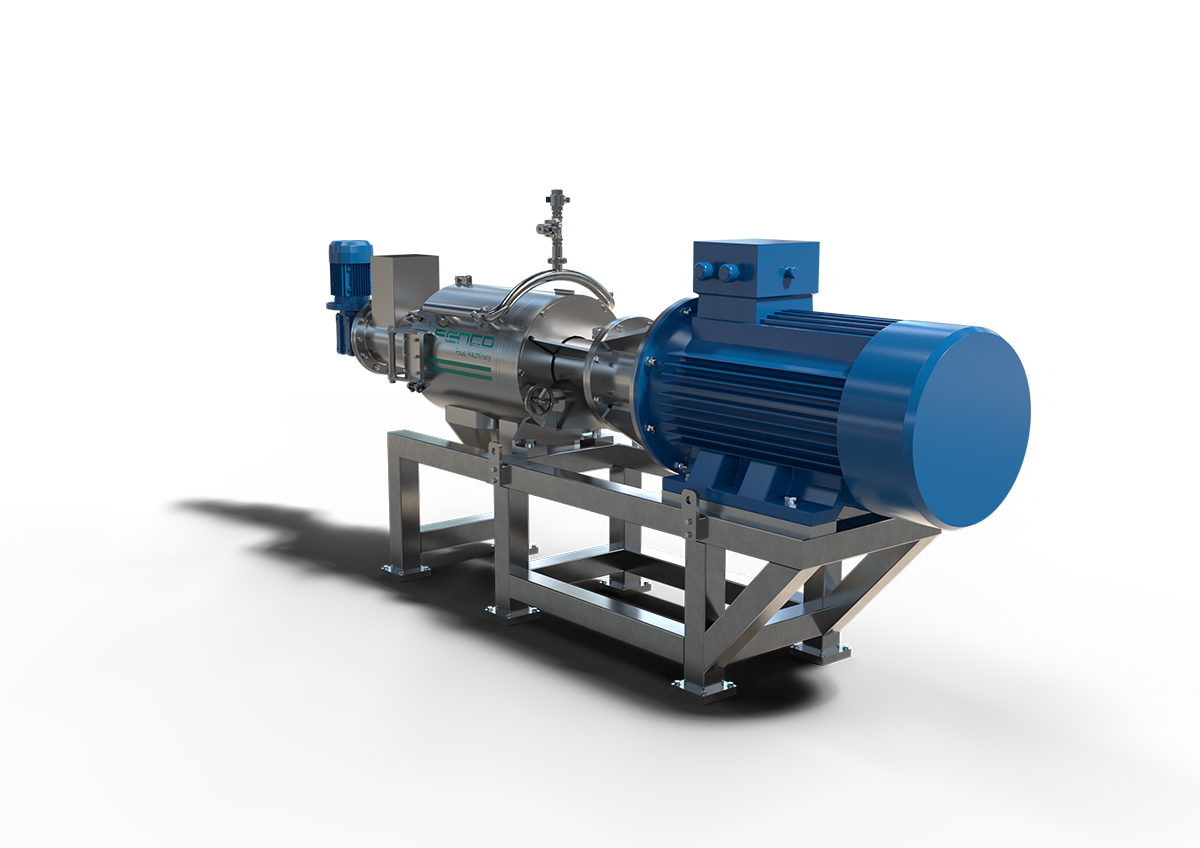

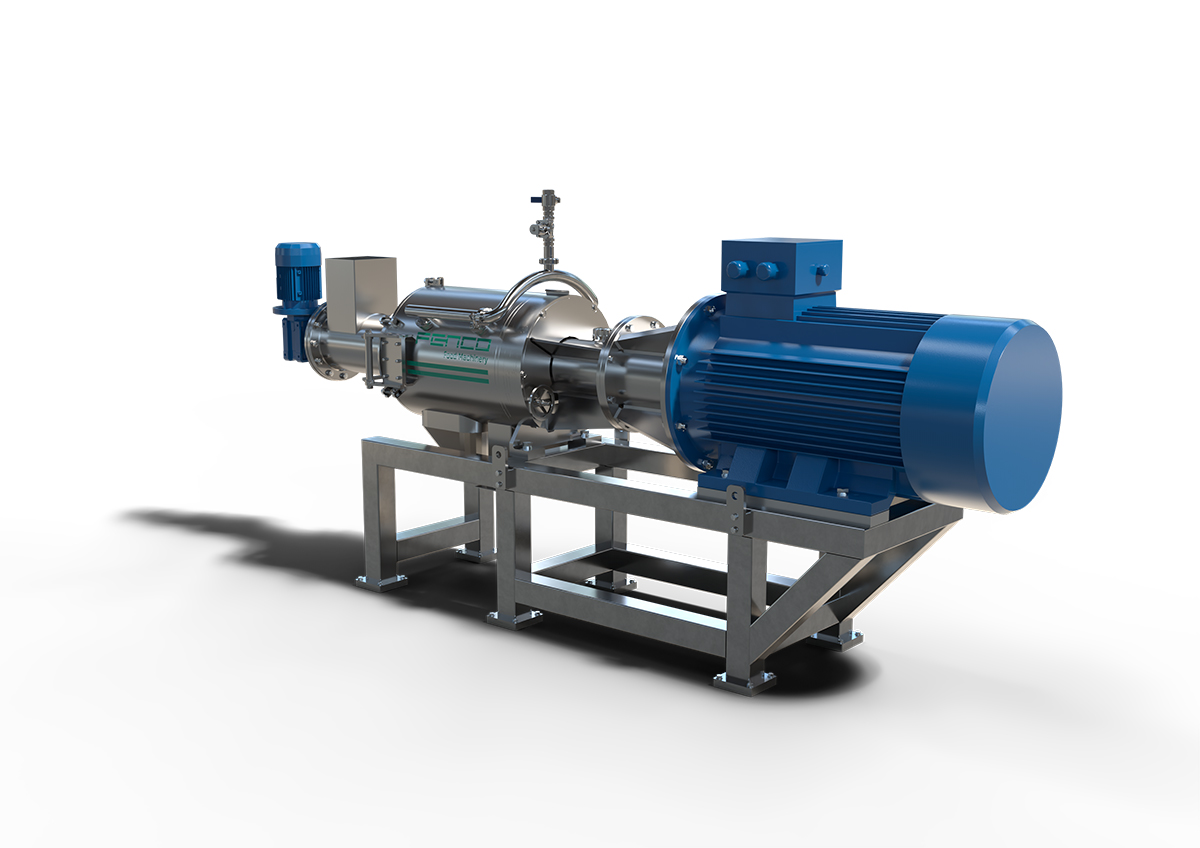

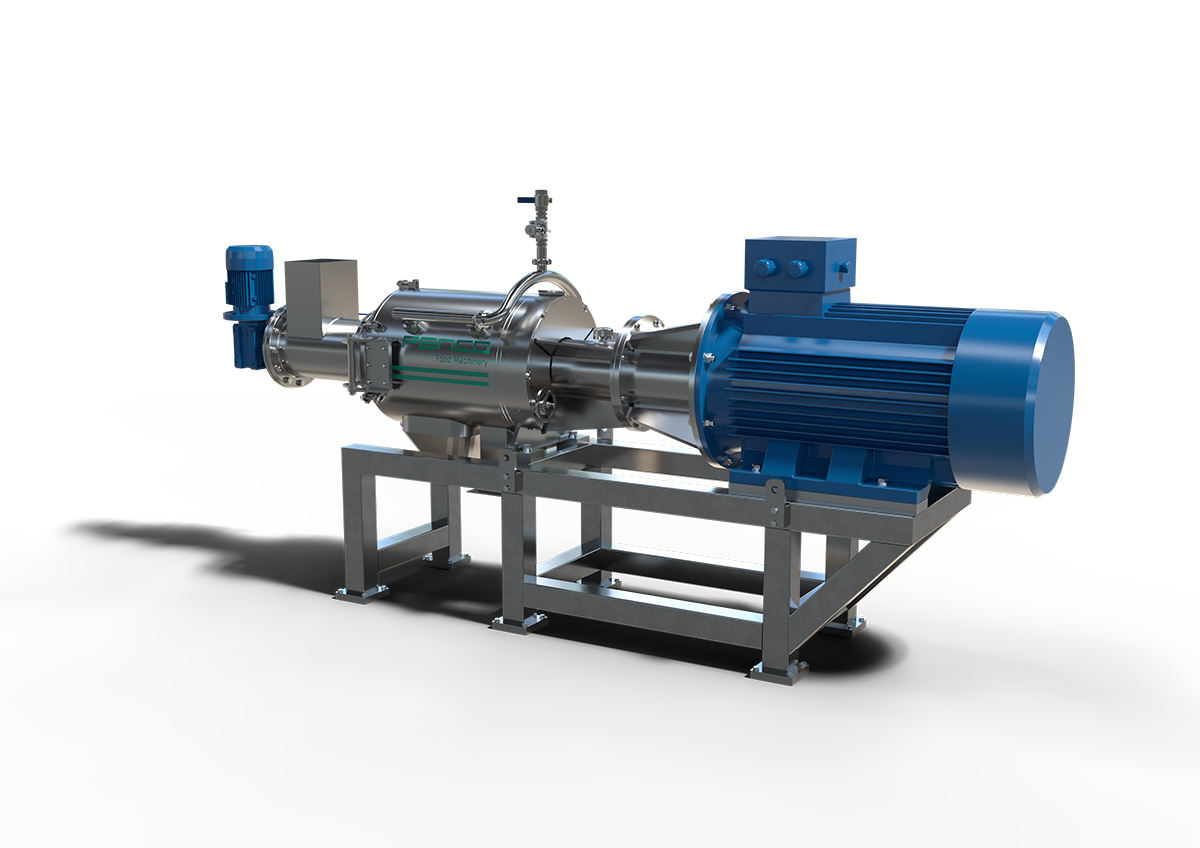

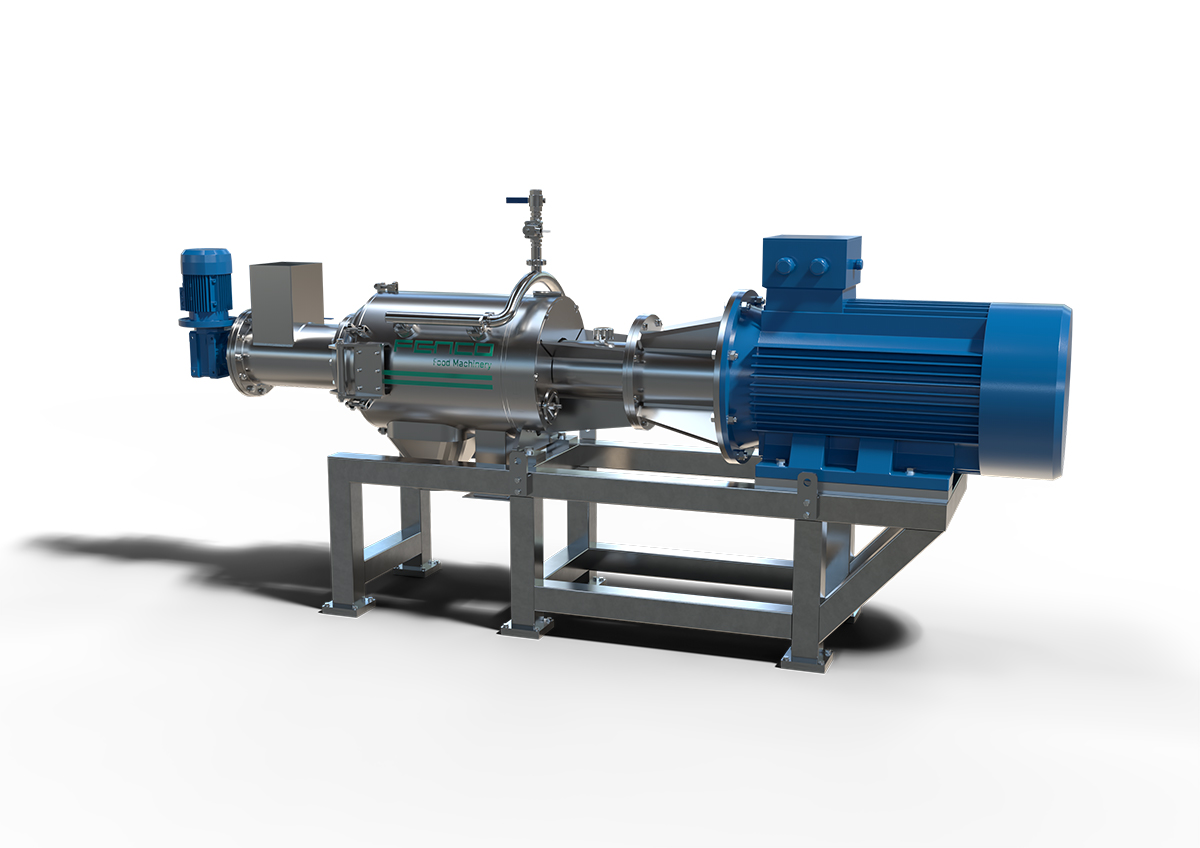

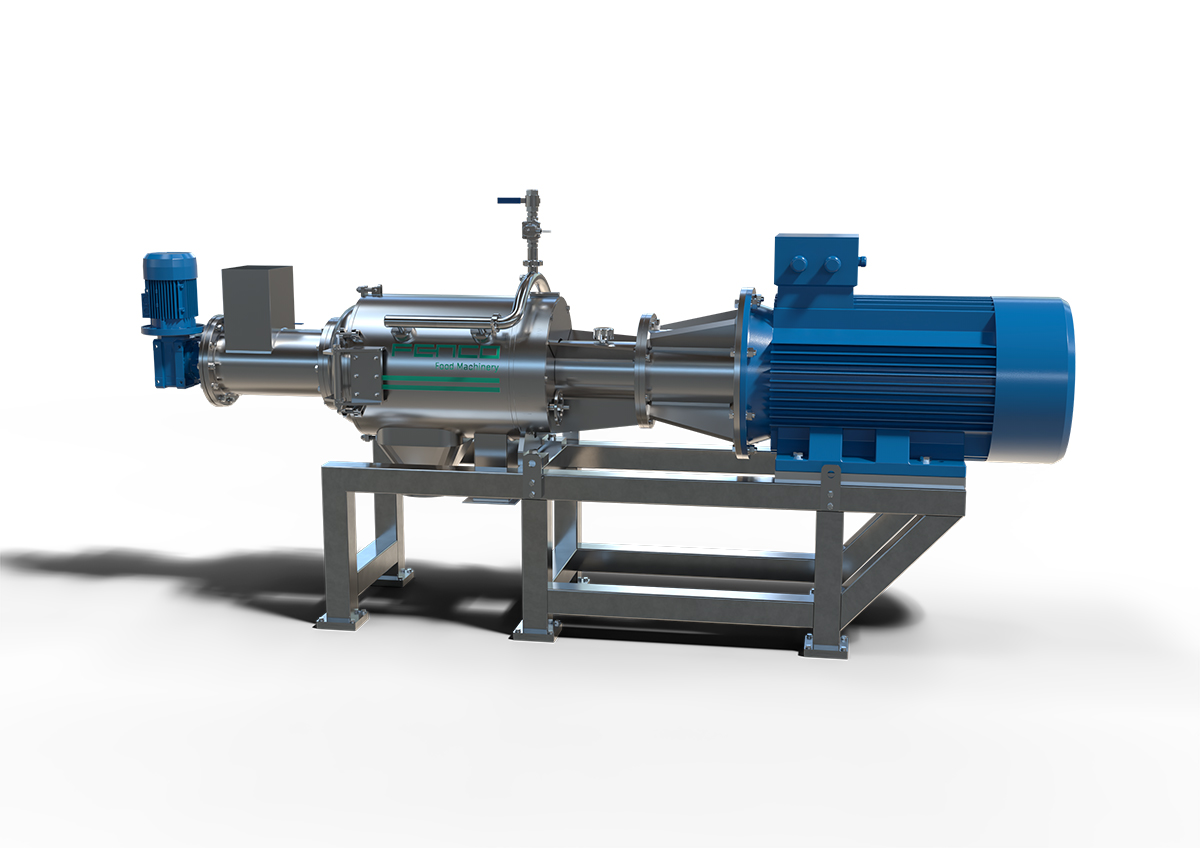

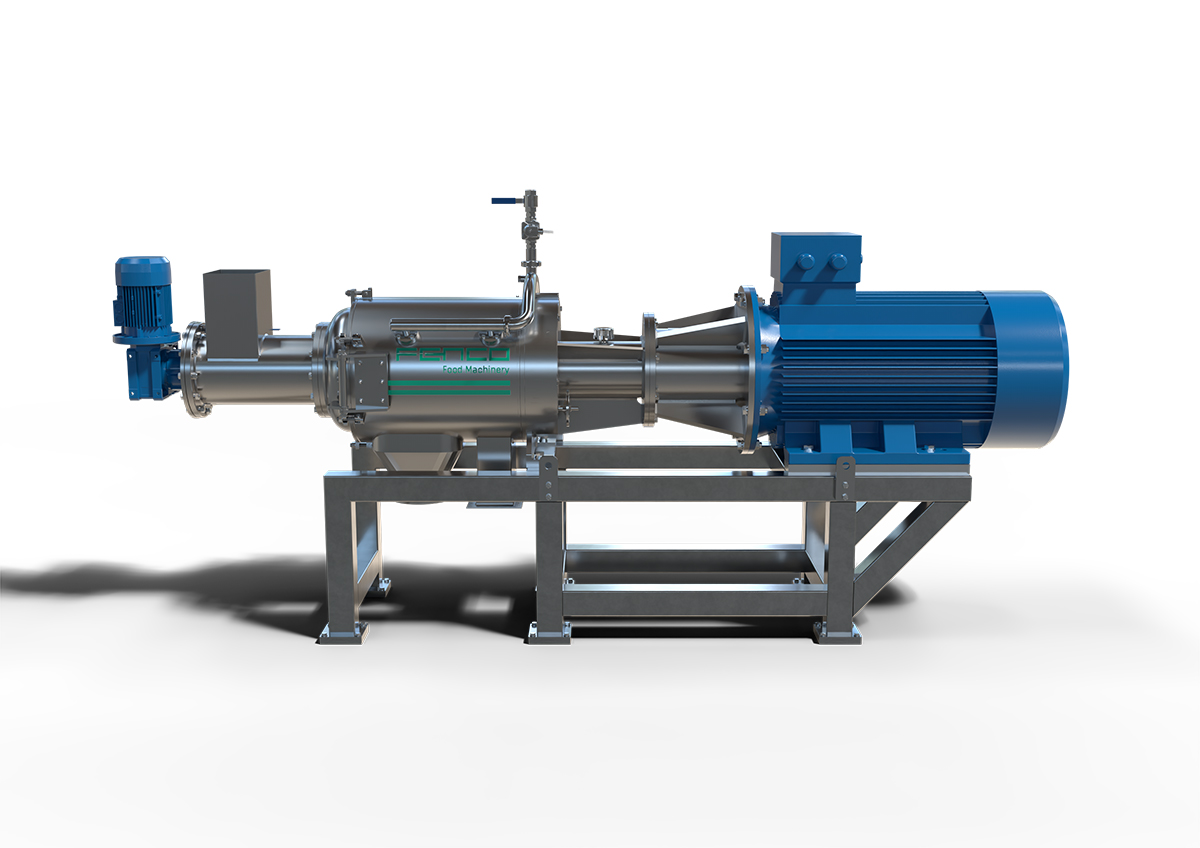

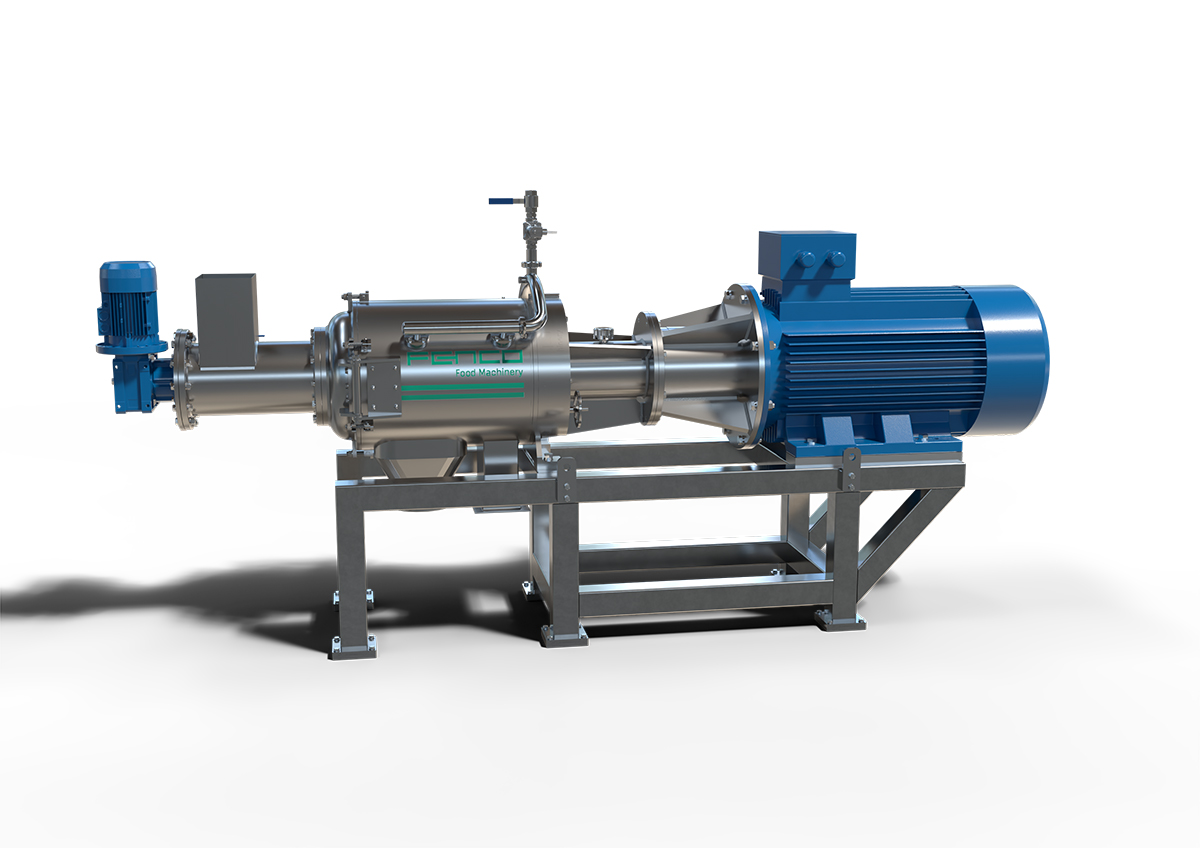

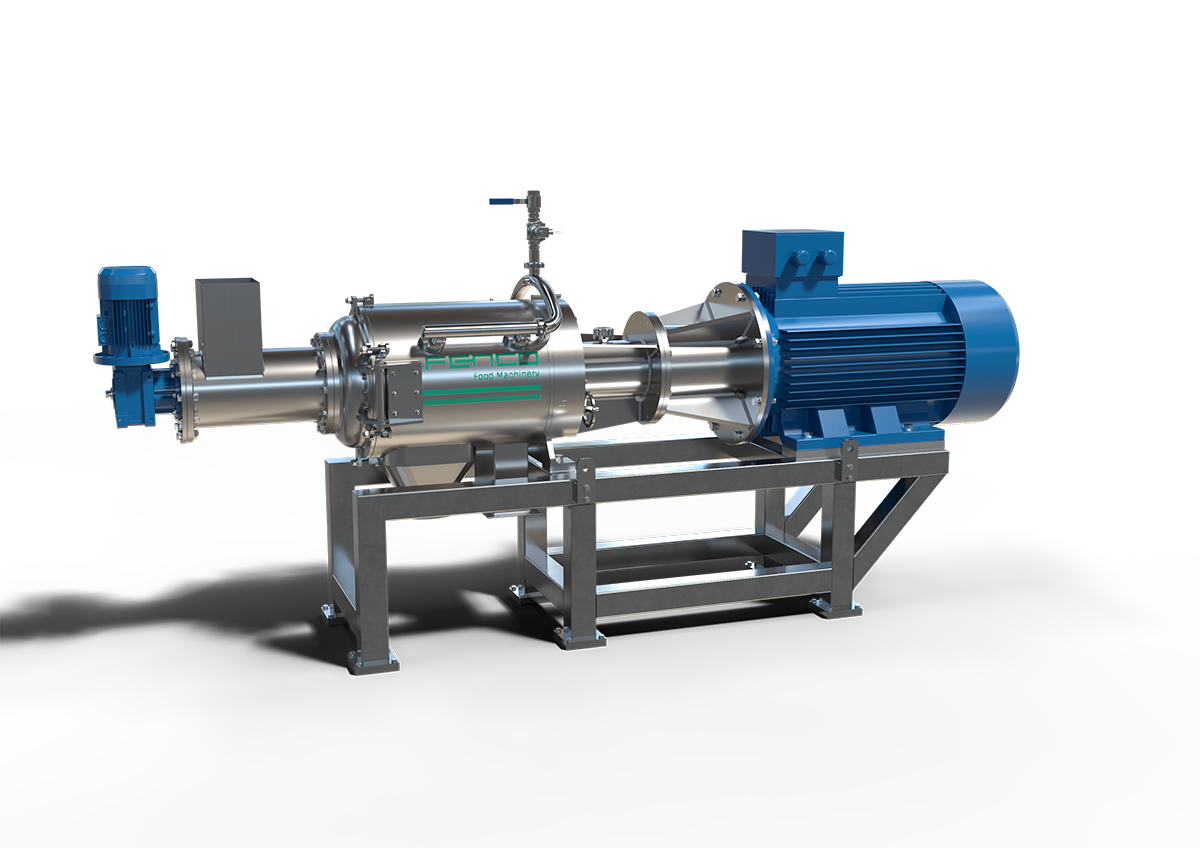

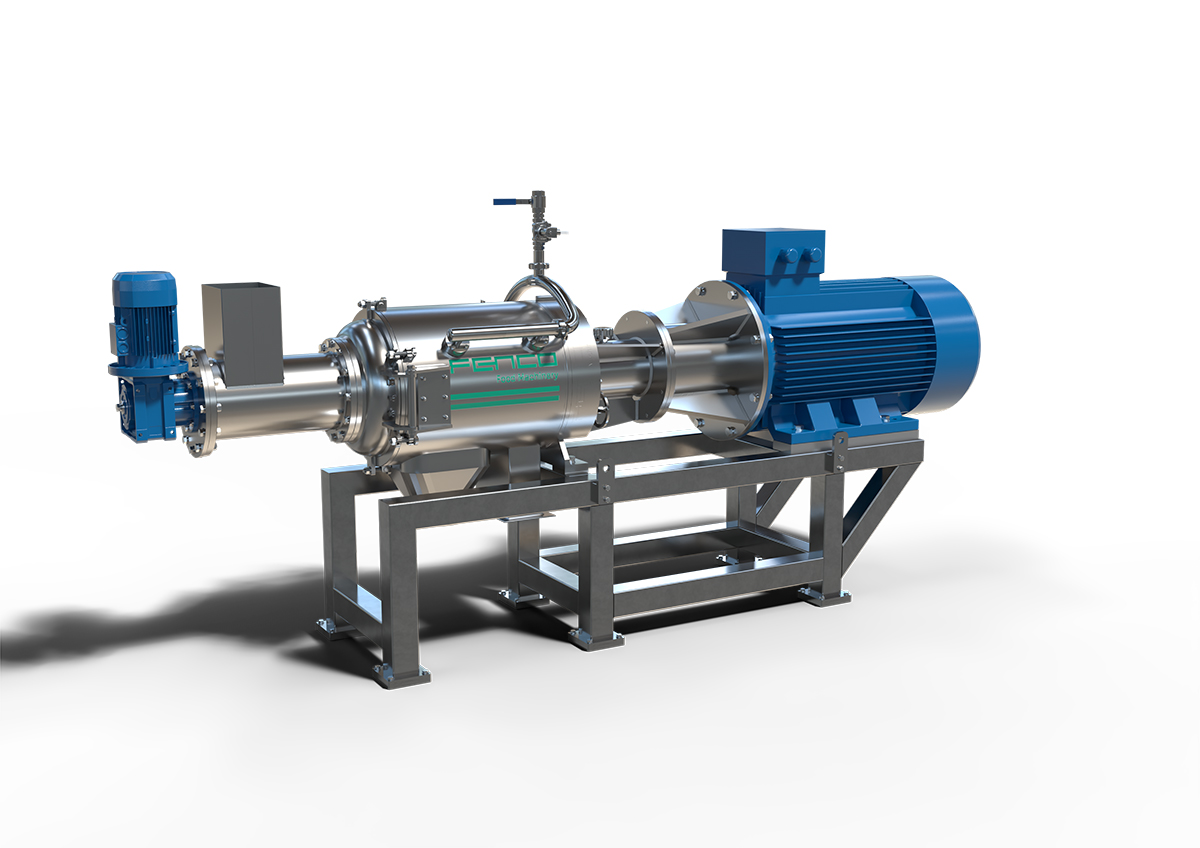

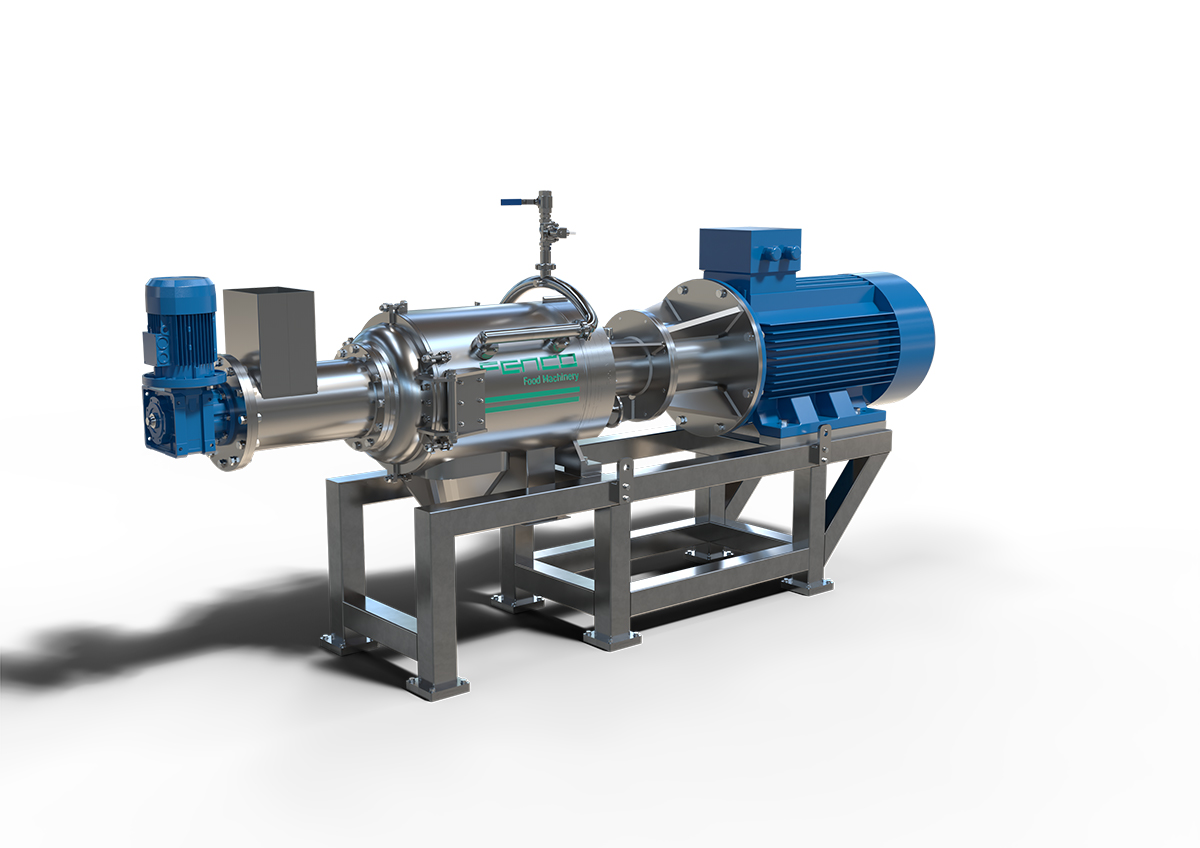

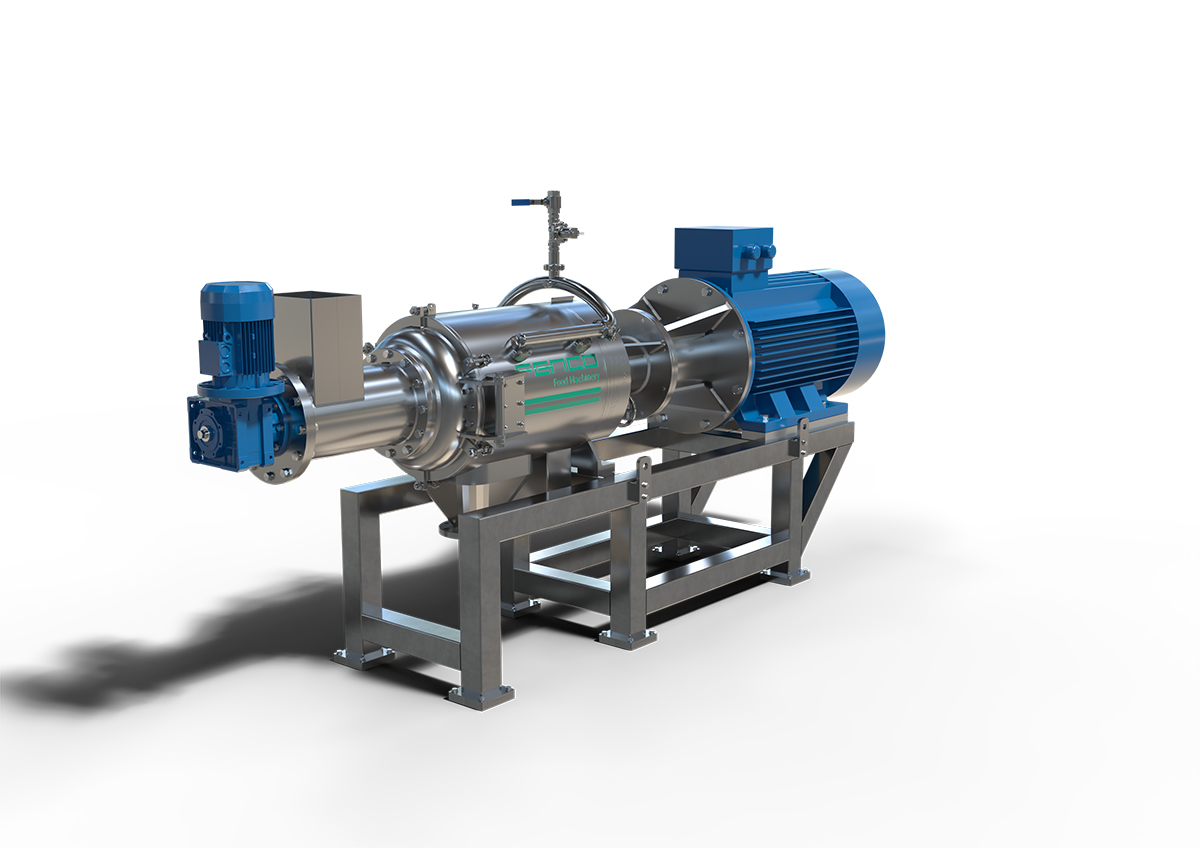

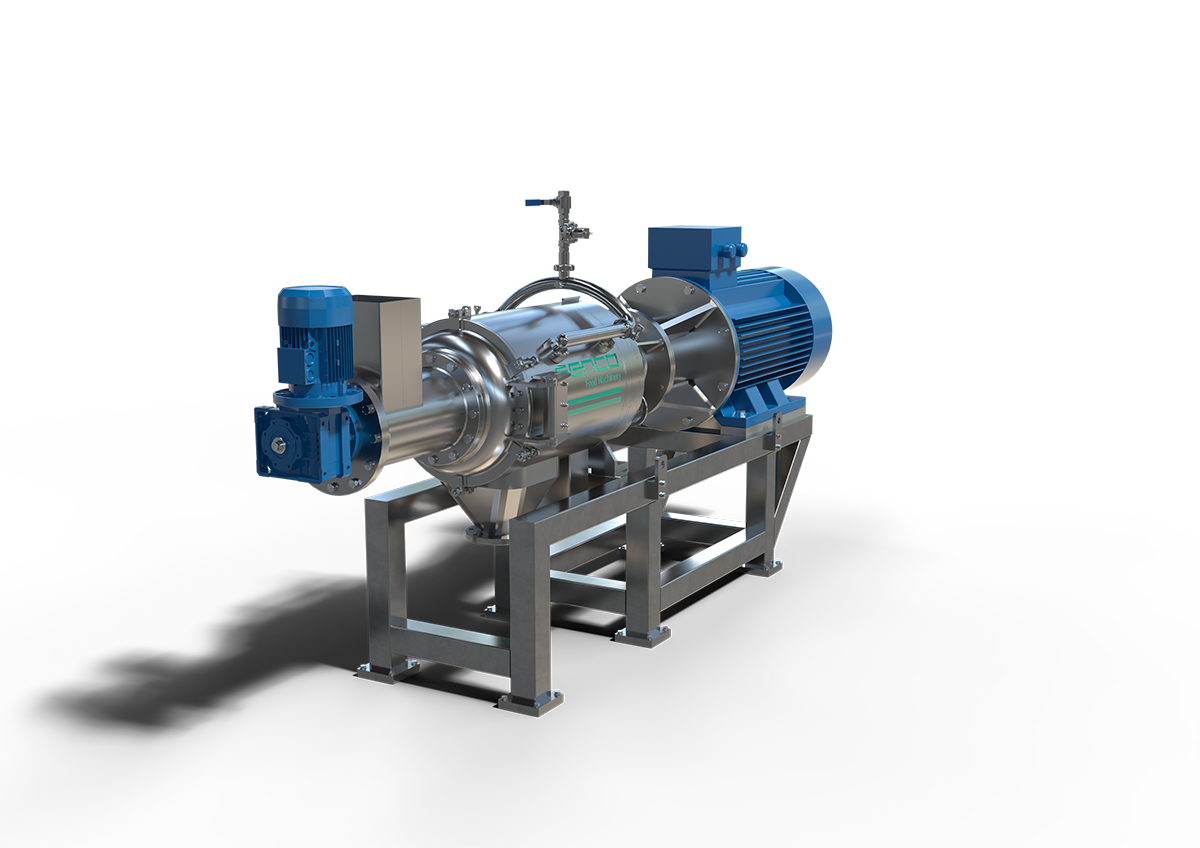

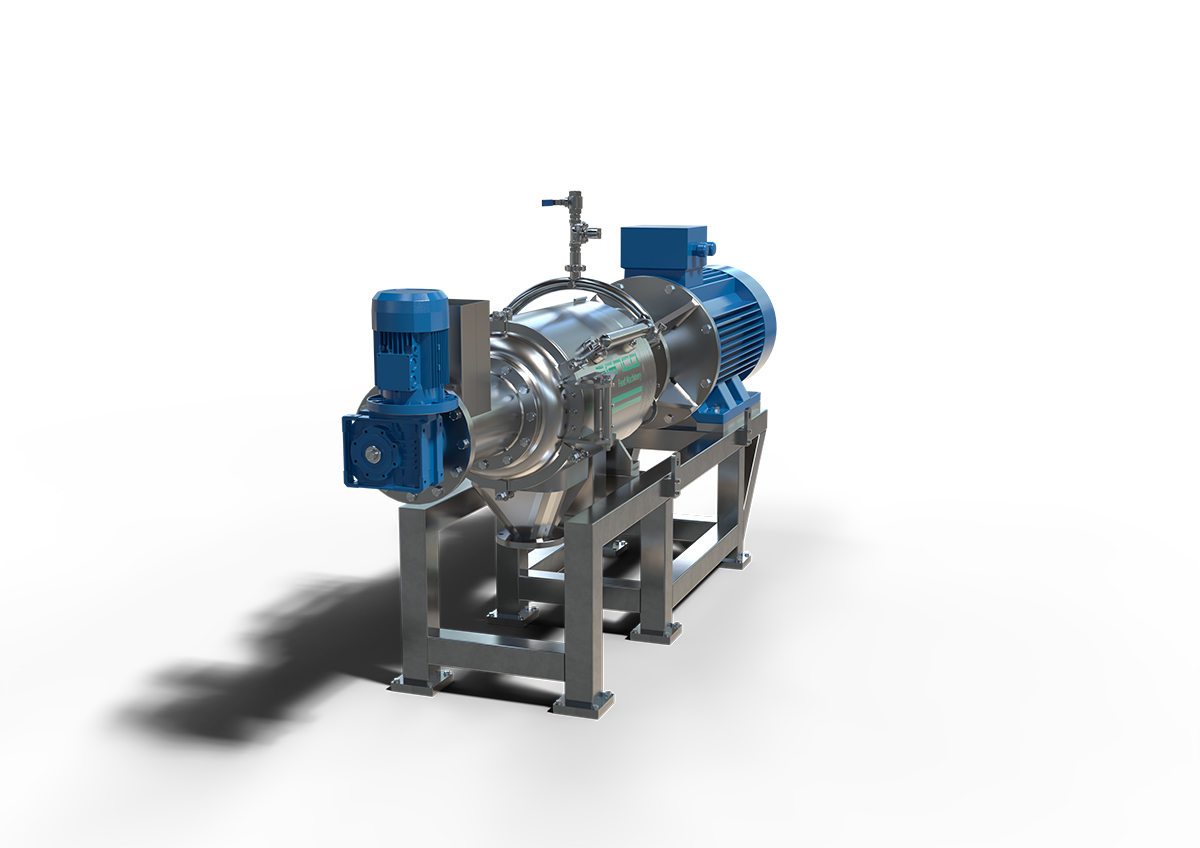

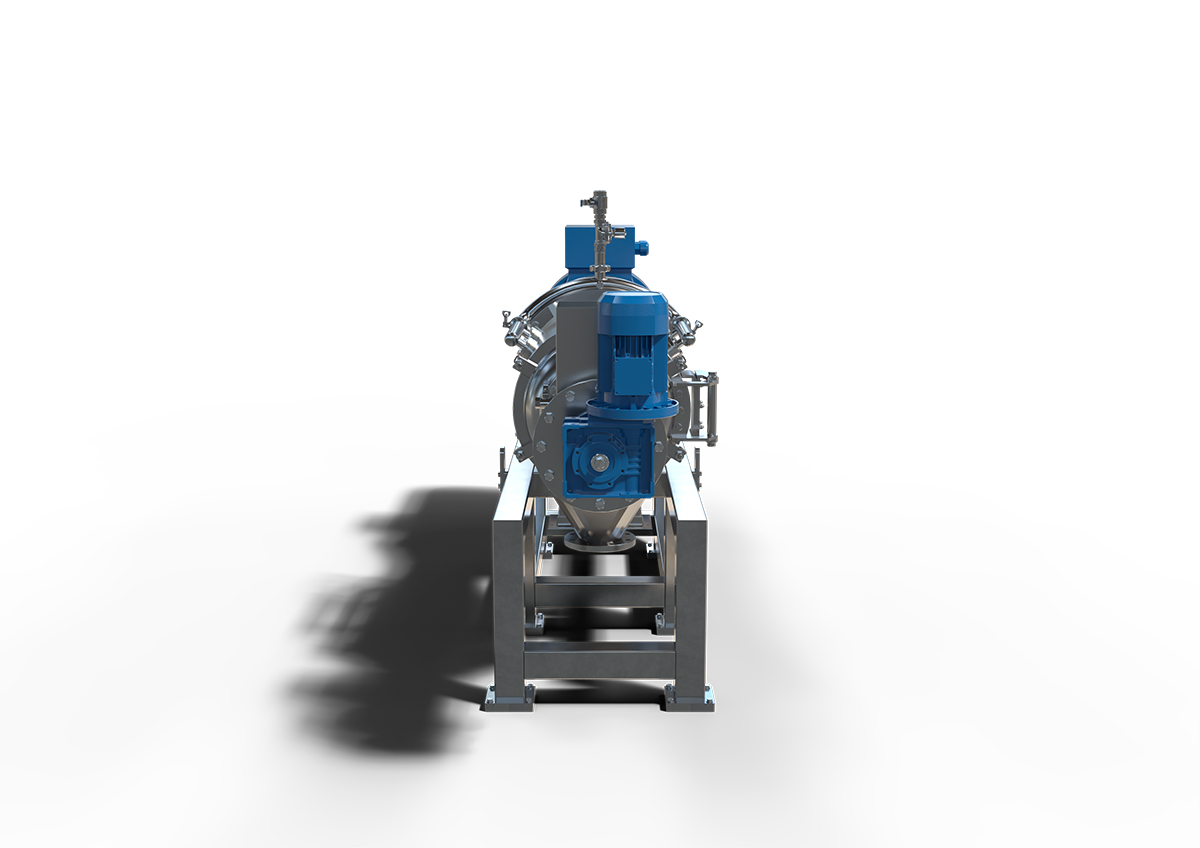

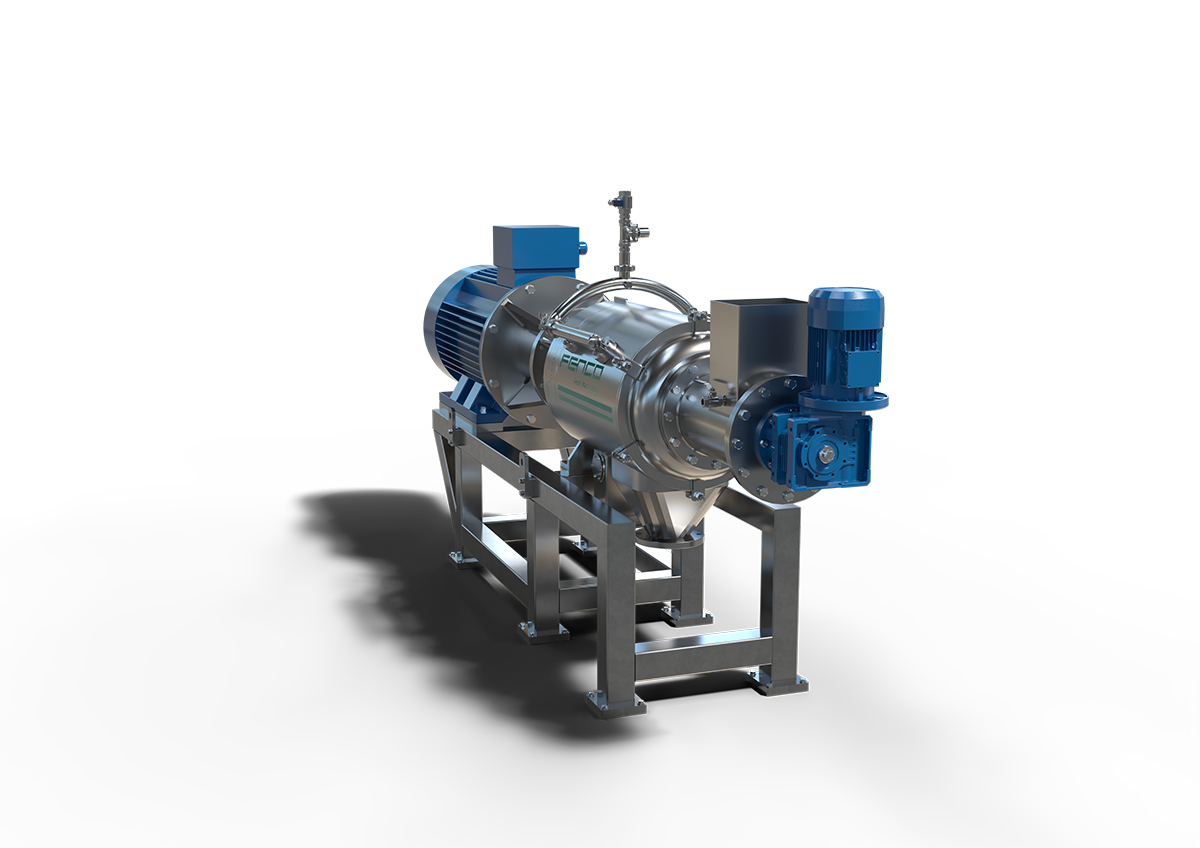

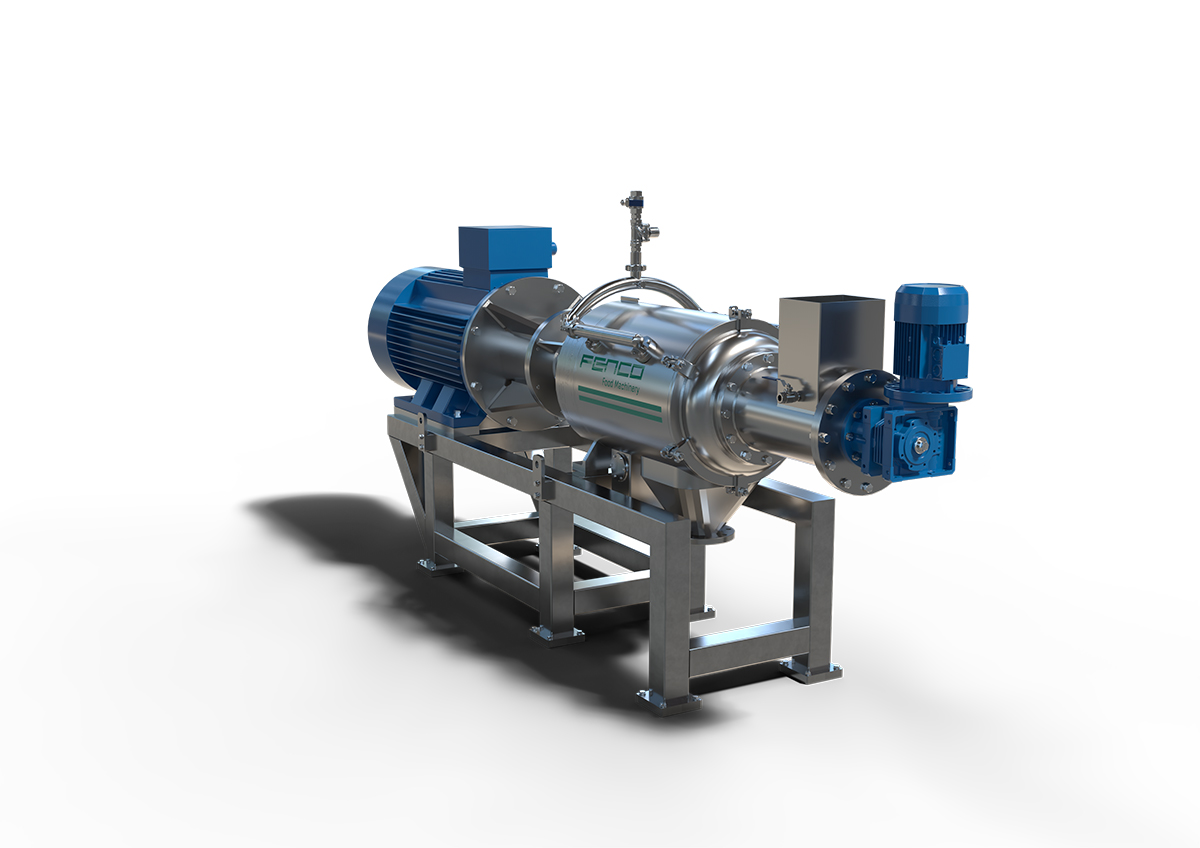

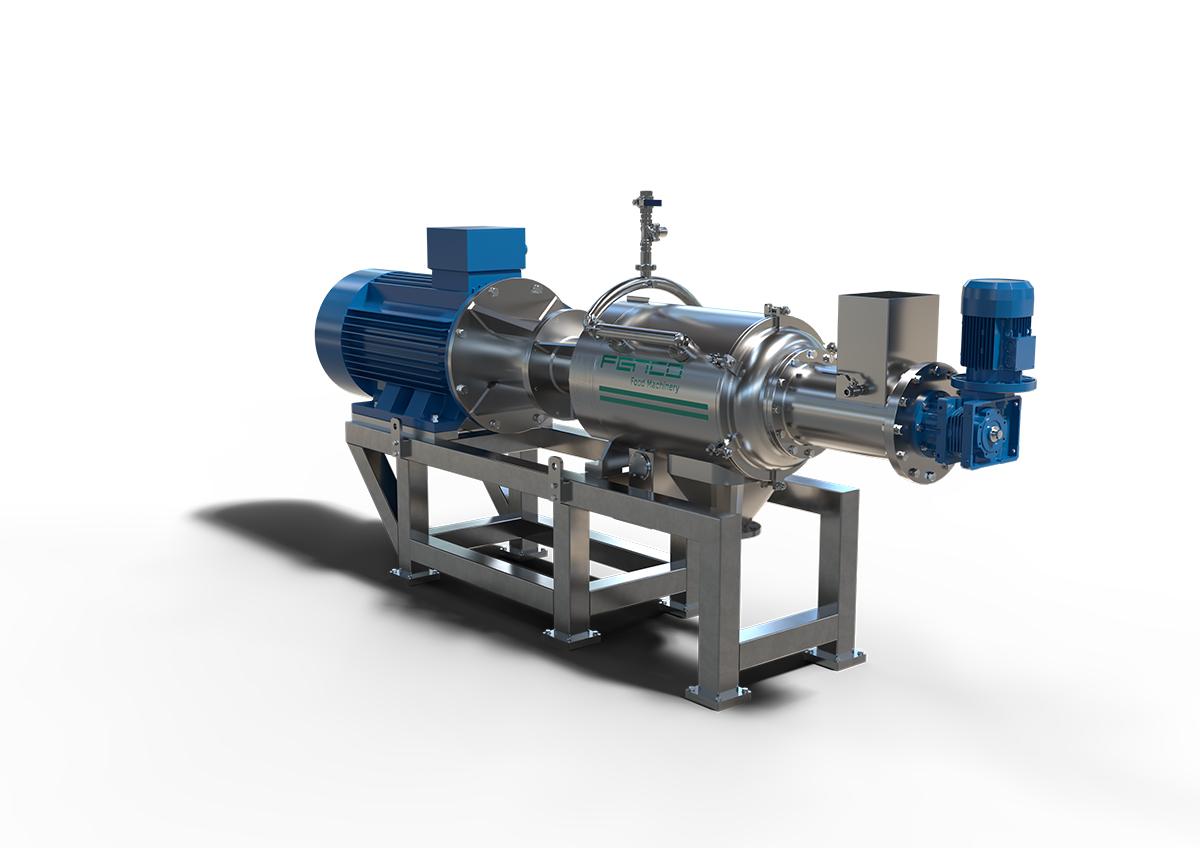

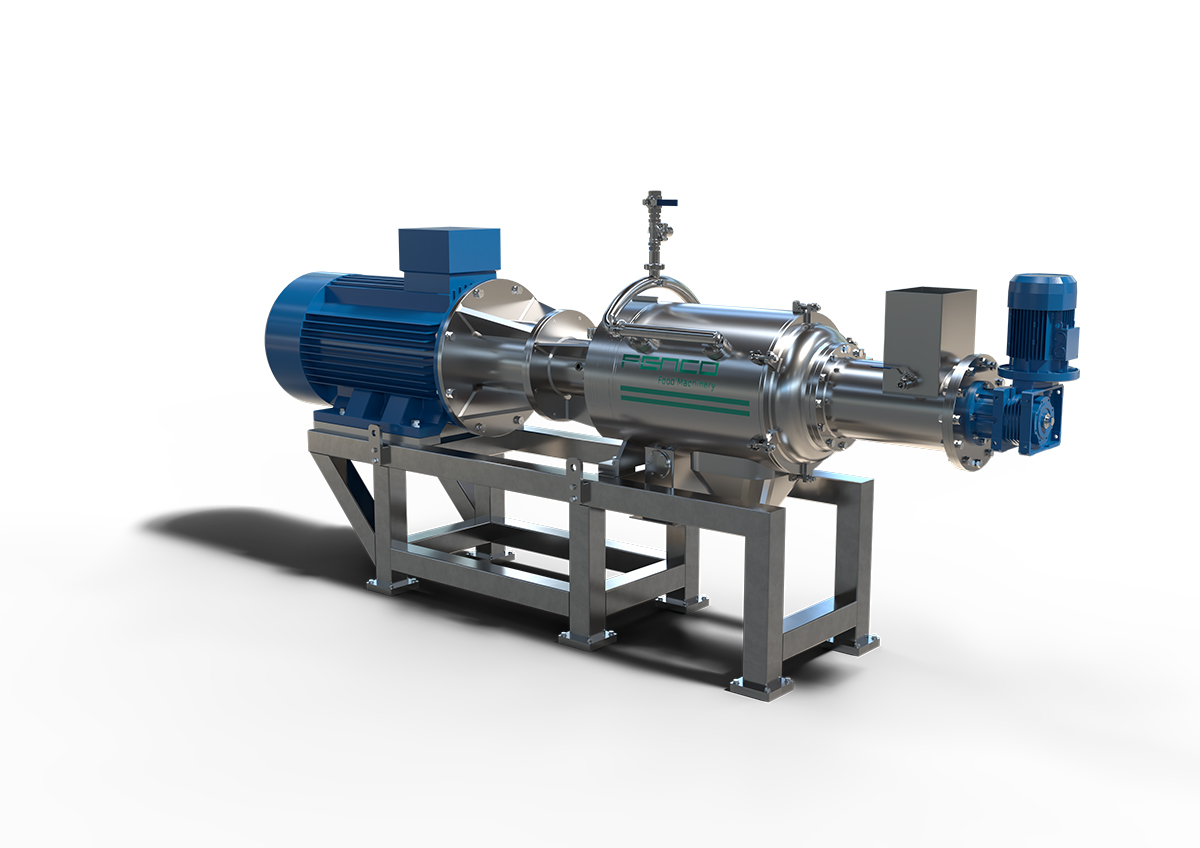

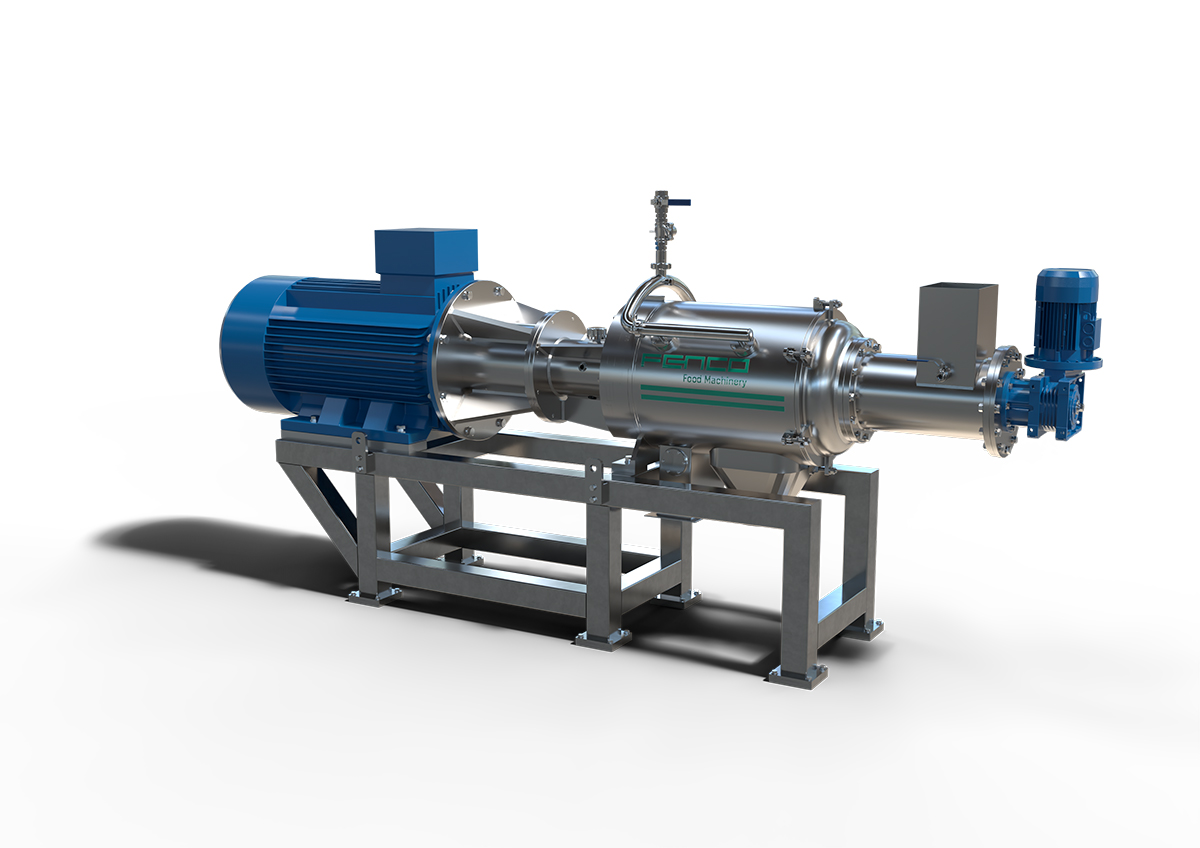

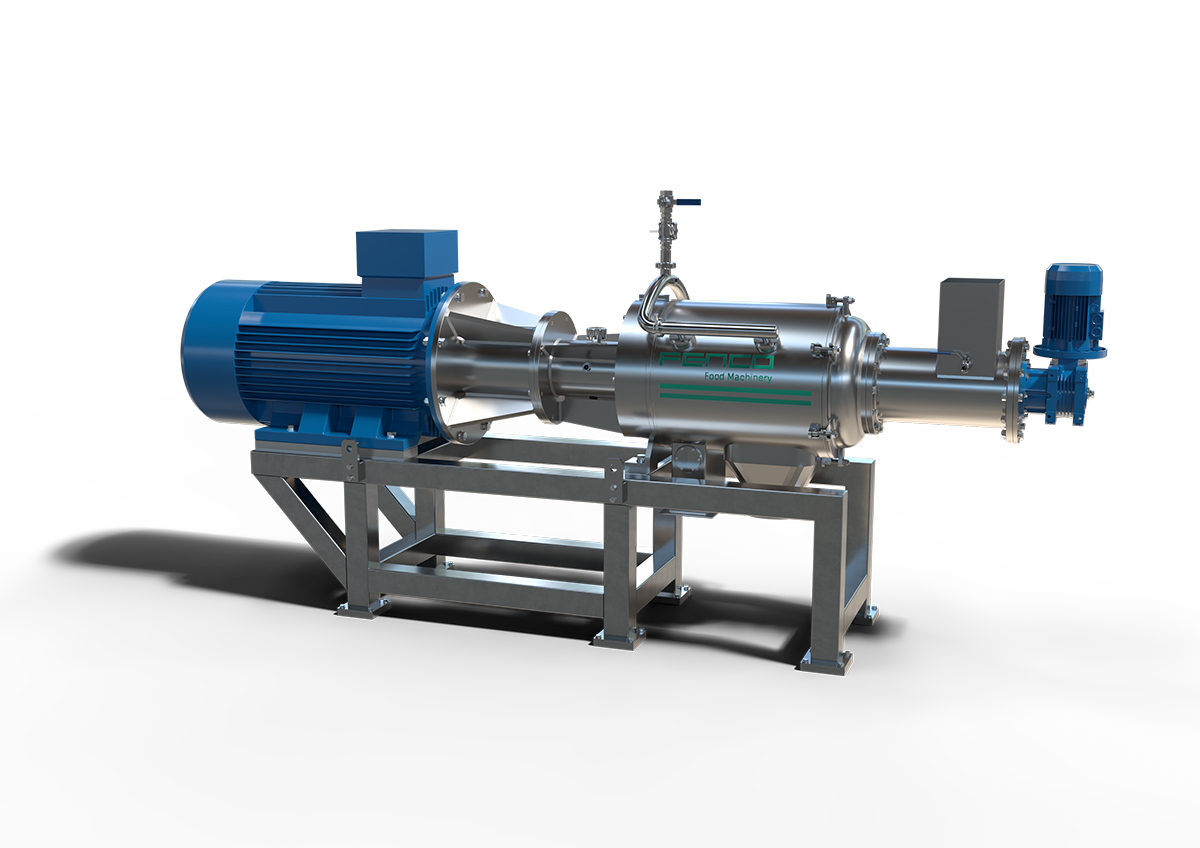

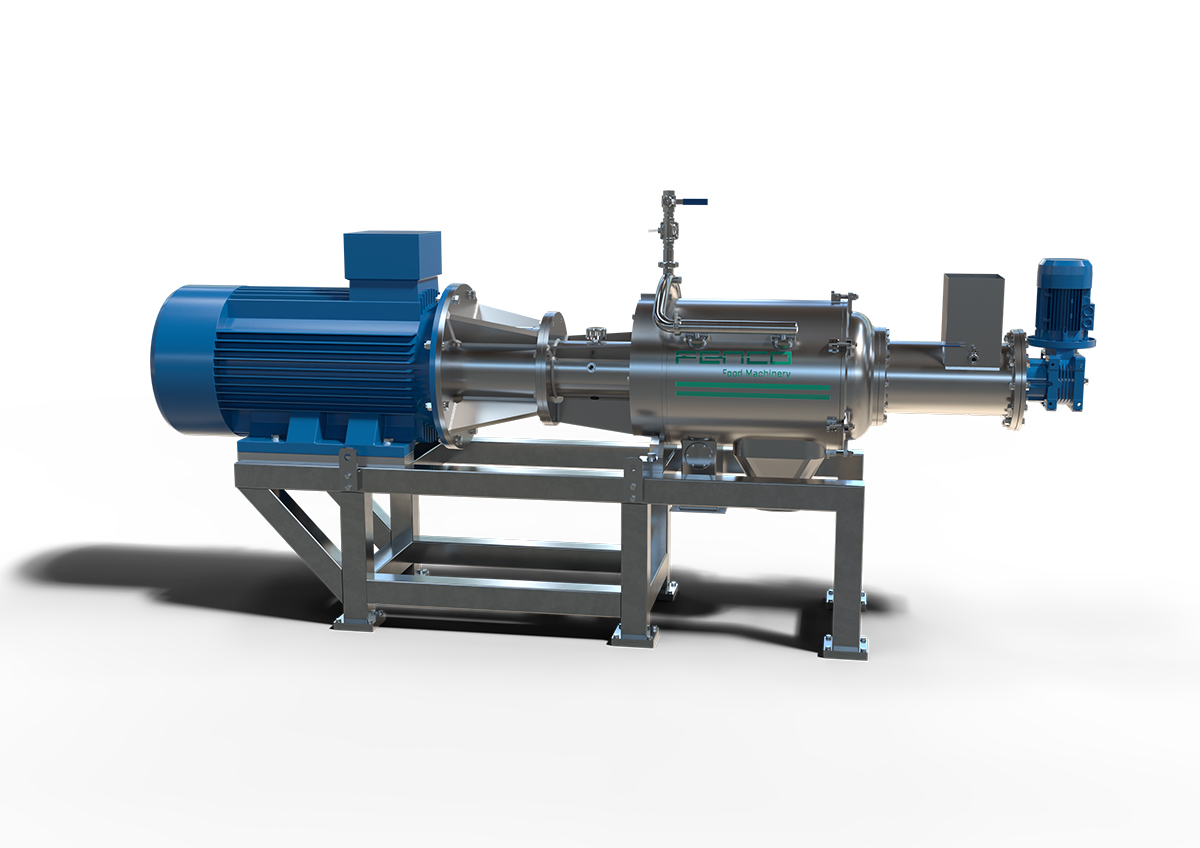

Pulper finisher machines

Pulpers are designed to separate impurities such as skins, peels, seeds, stems, and the like, in order to obtain purees and refined juices.

Production ranges from 5 to 60 t/h, in the case of tomatoes, to 3–15 t/h for cold extraction. Our pulpers can be assembled in simple or double stage.

Production ranges from 5 to 60 t/h, in the case of tomatoes, to 3–15 t/h for cold extraction. Our pulpers can be assembled in simple or double stage.

The key points of our pulp refining machines?

- Robust structure and heavy-duty design for 24/7 processing.

- All stainless-steel components.

- Possibility to have the sieves in a perforated plate with high thickness.

- High performance, with a high quality of finished product.

- Wide adjustments, rotor turns, and sieve rotor distance.

- Possibility of screw feeder for cold extraction.

- Optimized mechanics for intuitive maintenance.

- Integrated washing system with internal nozzles.

Are you interested in a pulp refining machine?

Fill out and submit this form: one of our experts will contact you shortly to answer your questions.